Freshness

Julie Turgeon / 2018

Yale School of Architecture

Yale School of Architecture

“Because the rhymes I say, sharp as nail

Witty as can be and not for sale

Always funky fresh, could never be stale.”

—Run-DMC, Run-DMC, “Rock Box,” 1983

The term “fresh” is laden with positive value assumptions, as evidenced by its slang use to denote high quality, original content in the 1980s hit single “Rock Box” by vanguard hip hop group Run-DMC. The song’s lyrics pit the rappers’ “fresh” rhymes in opposition to the antagonistic quality of staleness. The fresh/stale dialectic the song tees up evokes the use of the term “fresh” in a more quotidian context: as a favorable descriptor applied to the foods we consume. We are taught to value fresh meals (with the kinds of ingredients grown in a kitchen garden, which—as journalist Michael Pollan would formulate it—“your great-great-great-grandmother would recognize as food”) over frozen dishes, and to steer clear of hyper-processed foods (with the kinds of ingredients manufactured in a factory and unceremoniously assigned barely-deciperable, chemical-esque, polysyllabic names).[1]

Freshness invokes quality, and is associated with health, purity, and simplicity. Freshness, especially in reference to produce, engenders certain assumptions, particularly with regards to the sourcing and post-harvest treatment of our food. There is an unspoken, general expectation that “fresh” foods are those which are made available to the consumer in conditions unaltered from their original or natural (another tricky adjective) state—free from chemical adulteration, genetic manipulation, or physical alteration of any sort. Grocers cater to the guise of freshness not only through the use of the term “fresh” in signage and labeling, but through performative acts like misting produce, presenting the shopper with dewy, gleaming fruits and vegetables, seemingly just plucked from the earth.[2]

Moreover, the quality of freshness is often correlated with short geographic distance between source and destination, a topographical reinterpretation of Occam’s razor applied to the modern western diet, equating the shortest distance with simplicity, and simplicity with value.

Contemporary trends in dining and restauration reflect these assumptions: the farm-to-table model, for example, promotes a minimum-distance, minimal-alteration approach to food as it travels from farmer to fork, which is mainly achieved by bypassing commercial vendors and sourcing directly from a select few farms. This model has rapidly become a pinnacle of fine (as in tasty, but also ethical) dining for a well-todo class of conscious consumers.[3] Similarly, “eat local” has become the mantra of a generation of foodies, many of whom recognize and deploy their consumption habits as political choice.

At a time when over half of the world’s population lives in urbanized areas, removed from the sources of the agricultural products that provide its sustenance, the “fresh” label attempts to frame a (admittedly superficial) shared understanding of the sources of our food.[4] Despite most peoples’ distance or removal from the practice of agriculture, the designation “fresh” provides a semblance of comfort through the assumed control members of society can exercise over their diets through choices made regularly at the grocery store.

![]()

Defining Freshness: Labeling, Legalities, and Loopholes

Fittingly, “fresh” has become a widespread label used in the branding, marketing, and advertising of food products as varied as milk, poultry, meat, juice, and of course produce. Though all have all laid claim to the adjective, the precise meaning “fresh” carries in these diverse circumstances varies significantly depending on the item in question: fresh milk implies something different than fresh rutabaga, or freshsqueezed orange juice, for example. Prior to 1993, the use of the term was unregulated, but the repeated “misuse” of the descriptor (and its cousin “freshly”) prompted the Food and Drug Administration (FDA) to propose a legalized definition of the modifier and establish federal regulations to govern its use on labels and packaging.[5] These were enacted into law in 1994, following an open discussion in which industry experts, government officials, and the general public were invited to participate.[6]

In 2000, the FDA held yet another open hearing to determine whether to amend the definition of “fresh” in light of several novel technologies available to extend the shelf life of produce, like the use of pulsed electric fields and of high pressure processing.[7] The questions posed at both the 1993 and 2000 meetings reveal the fraught nature of these discussions involving many players—lobbyists, activists, consumers, producers, retailers, shippers, distributors, lawmakers—with often-competing motivations, and the challenges of setting standards to universalize a largely subjective quality like freshness:

Do consumers associate the term “fresh” with organoleptic [sensory], nutritional, or some other characteristics? What does industry think “fresh” means? Are there quantifiable parameters, e.g., level of nutrients or vitamins, that could be measured to determine if a food is “fresh?” Do consumers want a way to identify foods that taste and look fresh but have been processed to control pathogens?[8]

The more general questions latent in these pointed inquiries include: Is it possible to measure freshness?[9], When is it okay to distinguish something as fresh? Does freshness exist on a spectrum? Or is it a switch, something either present or not? As of 2017, the regulations remain the same as when they were originally instituted in 1993. The code reads as follows:

“The term fresh, when used on the label or in labeling of a food in a manner that suggests or implies that the food is unprocessed, means that the food is in its raw state and has not been frozen or subjected to any form of thermal processing or any other form of preservation.”[10]

The following exceptions are then called out, which do not preclude food from being deemed “fresh”:

1. the addition of approved waxes or coatings;

2. the post-harvest use of approved pesticides;

3. the application of a mild chlorine wash or mild acid wash on produce; or

4. the treatment of raw foods with ionizing radiation. [11]

This list of exemptions begins to hint at the immense logistical apparatus that the fresh produce supply chain participates in, breaking the illusion of the “fresh” as having been subject to minimal intervention and foregrounding instead the sequence of spaces and processes dedicated to preserving freshness along the supply chain, particularly the fresh produce supply chain. This network of spaces and operations devoted to freshness will be dissected in the following pages.

Before tackling the produce supply chain as spatialized network, it is worth noting a few key facts about plant biology which ultimately constitute the raison-d’être of the network’s various precipitate operations. Many of the difficulties surrounding the definition and establishment of precise guidelines concerning “freshness” have to do with the term’s application to produce, which, by definition, is alive: it breathes, respires, transpires, matures, and eventually dies. Freshness, therefore, is always a moving target, uniquely constituted in each of the hundreds of varieties of fruits and vegetables that travel through the logistical systems of produce distribution networks across the country every day. Because it is tasked with the tremendous challenge of keeping produce healthy through journeys often totaling hundreds, if not thousands, of miles between harvest and consumption locations, the fresh produce supply chain is the most complex supply chain in existence. With half of an item’s shelf lift typically spent in transit, the entire constellation of actors, vehicles, spaces, and contexts comprising the fresh produce supply chain is part of a grand-scale fight against the lifecycle of particular fruits and vegetables.[12]

The supply chain is smattered with peculiar spaces whose mission is essentially to hack the process of maturation of the produce it oversees, geared towards the mission of delivering the freshest possible produce to the hands of the consumer at the ultimate point-of-sale, be that a restaurant, bodega, supermarket, or café. The many equipment- and technology-intensive specially-designated spaces involved attempt to rein in the ripening process in order to control and predict the optimal freshness of the crop in their purview.

These are the spaces explored within the remainder of the pages herein, organized into three distinct categories based on the means they employ to manipulate (either through suppression or acceleration) the plant ripening cycle: physical, thermal, and chemical. Rather than provide a comprehensive taxonomy, this examination takes a cross section through the varied spaces constituting the fresh produce supply chain dedicated to the task of keeping these important commodities fresh.

Physical Means of Protecting Perishables

Produce is perishable; it would rot if not consumed within a certain amount of time. As soon as it is harvested, the various processes leading to breakdown begin. These processes can’t be stopped, but can be manipulated—slowed or hastened—and the fresh produce supply chain utilizes various physical means to control this natural cycle, so that the crop ultimately arrives to the consumer in optimum (read fresh) condition. This section addresses both the physical properties of fruits and vegetables, and the physical interventions routinely employed to maintain their attractive characteristics—including flavor, texture, and color—from initial pick to final destination.

All fruits, and many nuts and vegetables, can be classified into one of two categories: climeratic and nonclimeratic. Climeratic fruits continue to ripen after being picked, while non-climeratic fruits do not. For example, apples, bananas, mangoes, peaches, and avocados are climeratic fruits; berries, citrus fruits, and melons are nonclimeratic. Because climeratic fruits release plant hormones which trigger ripening, most notably ethylene, they must be kept away from other plants that are sensitive to these substances, lest the crop ripen and rot prior to reaching its destination.[13] Moreover, certain fruits and vegetables are sensitive to one another’s odors, and will absorb certain scents and flavors, often making for unsavory and unappetizing surprise taste combinations upon consumption. Leeks, for example, are known to pass their pungent, onionlike flavor on to figs and grapes, when stored in close proximity to each other. Green onions are especially licentious vegetables, spreading their flavor and odor to neighboring sweet corn, figs, grapes, mushrooms, and rhubarb, potentially destroying the viability of these latter more delicate-tasting varieties.

Growers, packers, shippers, and distributors therefore organize complex choreographies, in which certain items must be kept apart. In a process akin to crafting elaborate wedding seating charts, industry experts circulate (sometimes colorful) charts and graphics in an attempt to organize the unwieldy biology of these plants into clean, neat visuals summarizing compatibilities between crop types.[14] Though analog and seemingly simplistic, one of the most important means of preserving freshness in crops is to adhere to the appropriate physical separation guidelines removing antagonistic crops from each others’ vicinity. Not doing so could quickly and needlessly compromise a batch of otherwise viable (valuable) crop.

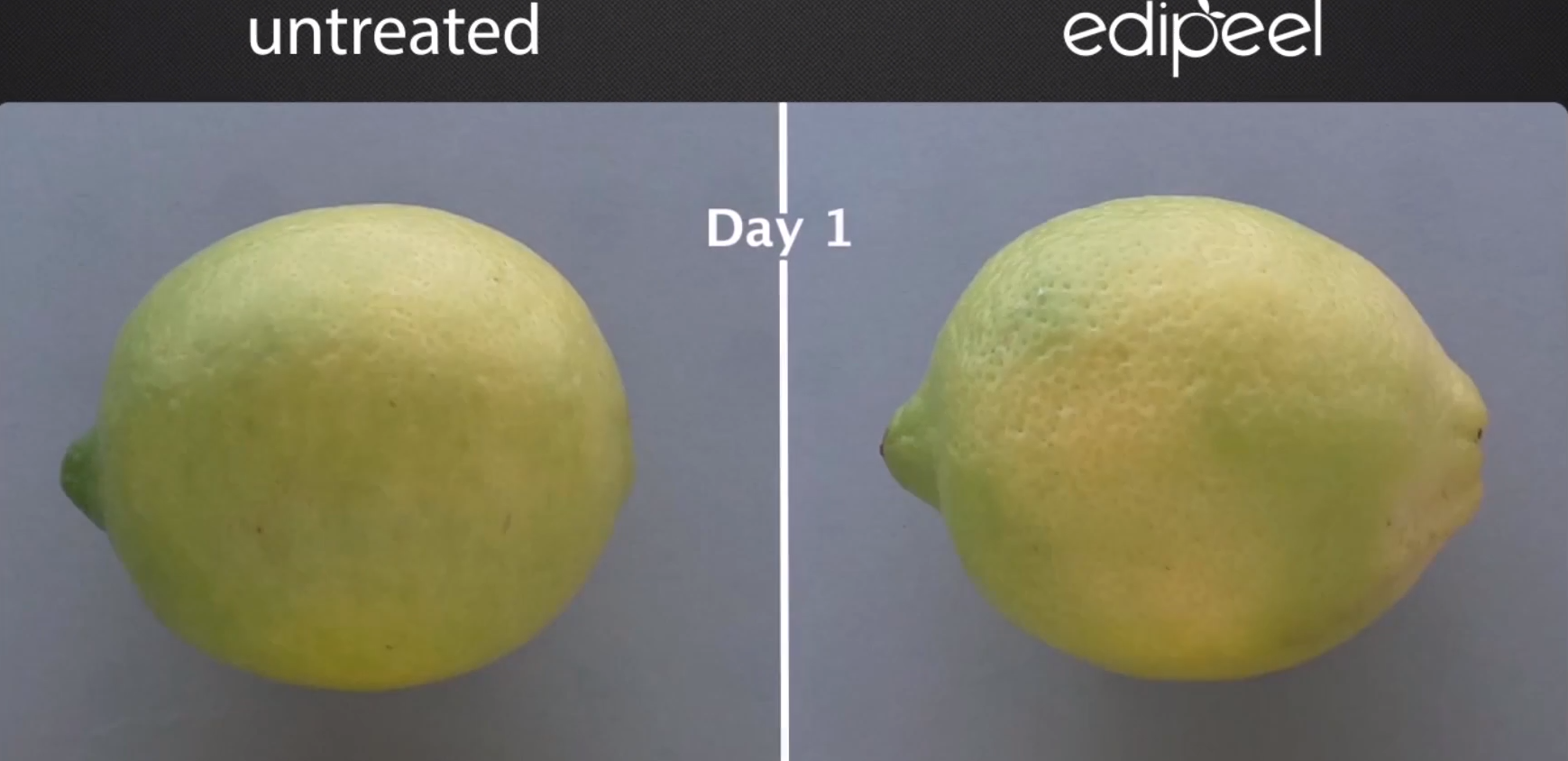

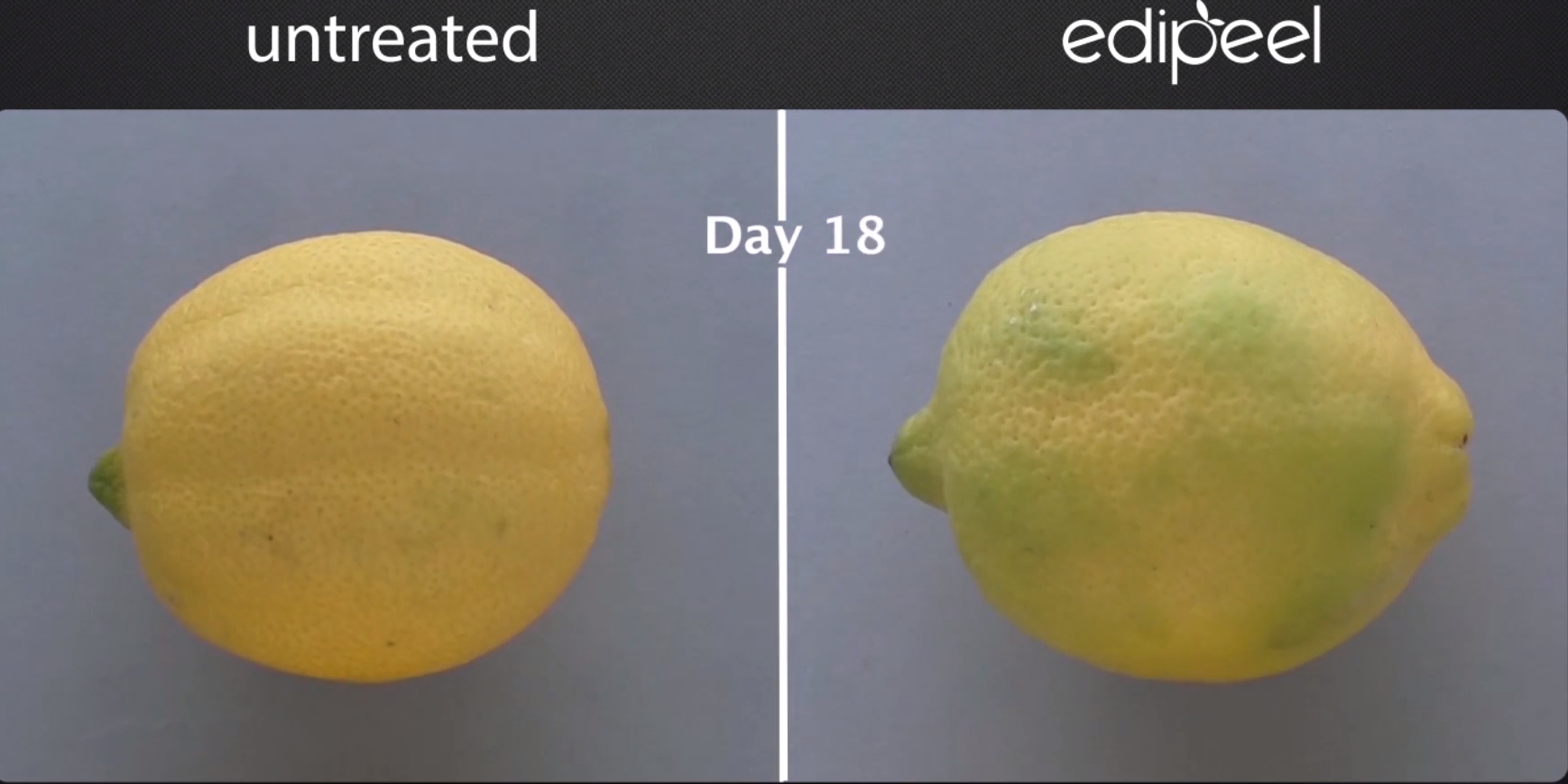

Prescribed positioning aside, another form of physical intervention associated with the fresh produce supply chain is the addition of (FDA-approved) wax coatings on produce. The wax treatment adds an virtually imperceptible, protective, tasteless, odorless layer to certain fruits and vegetables, including apples and peppers, which shield them from microbes while also extending their shelf lives by preventing dehydration. The Edipeel is one such waxing technology being developed; it is among the newest to hit the market, with a planned release this year.[15] These coatings—which are typically either natural-lipid- or petroleum-based—have the secondary effect of making items look more aesthetically pleasing through the added shine and glisten they often provide. Though the Edipeel certainly represents the newest of the type, protective produce coatings have been around for centuries: in the 12th and 13th centuries, Chinese citrusgrowers would pack their crop into wooden boxes, for example, before filling the boxes with wax.[16]

![]()

![]()

![]()

Fig. 1: lemon treated with Edipeel (right) versus without treatment (left)

![]()

![]()

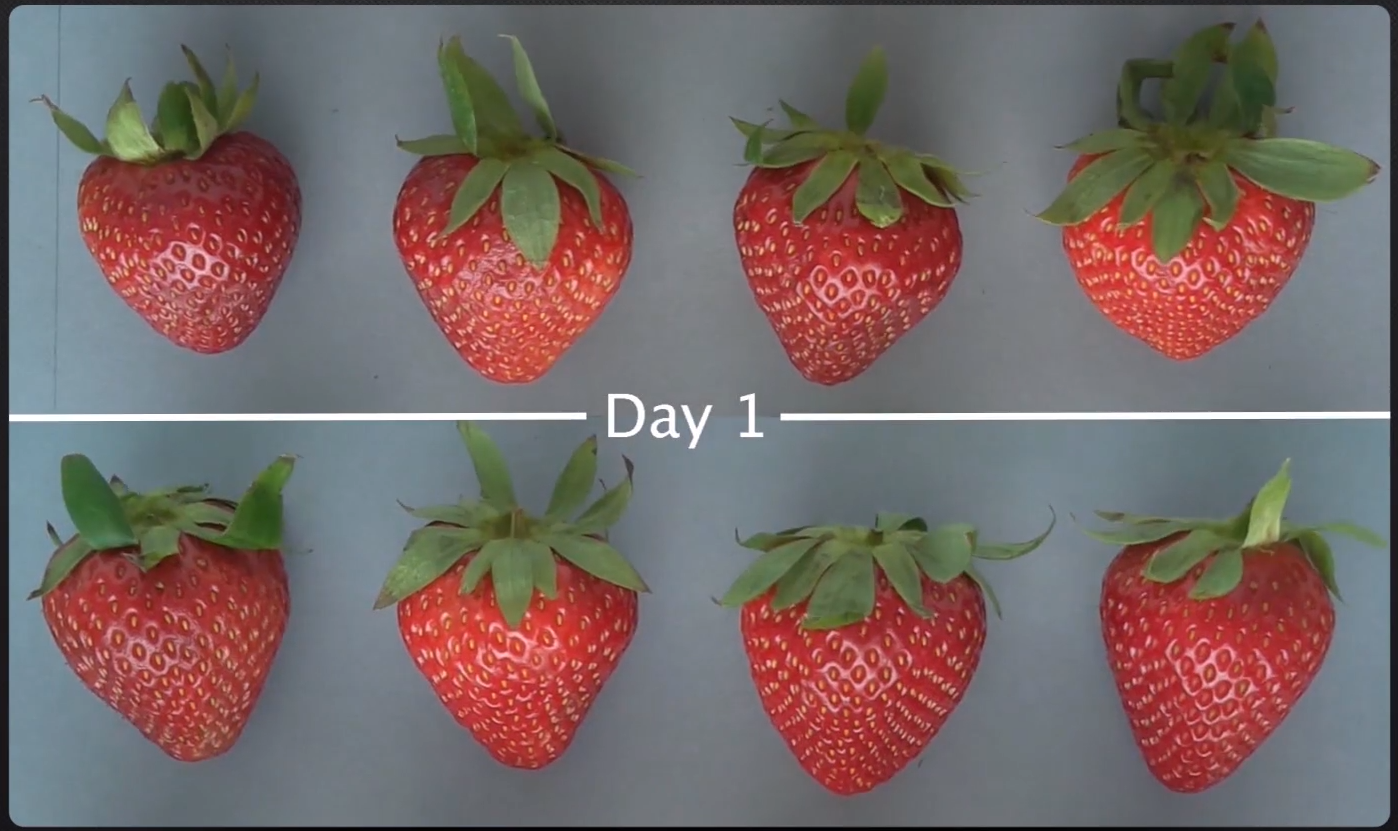

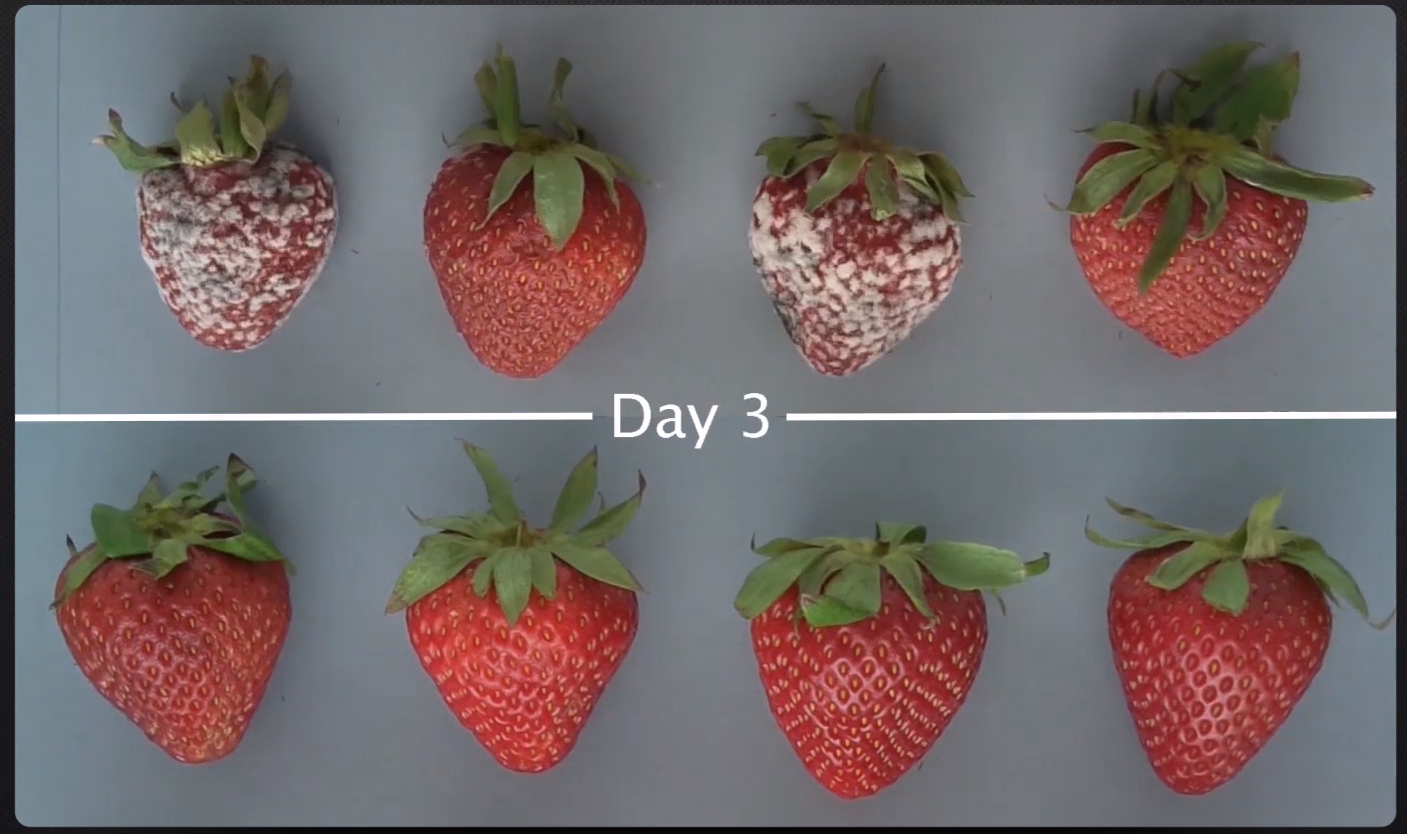

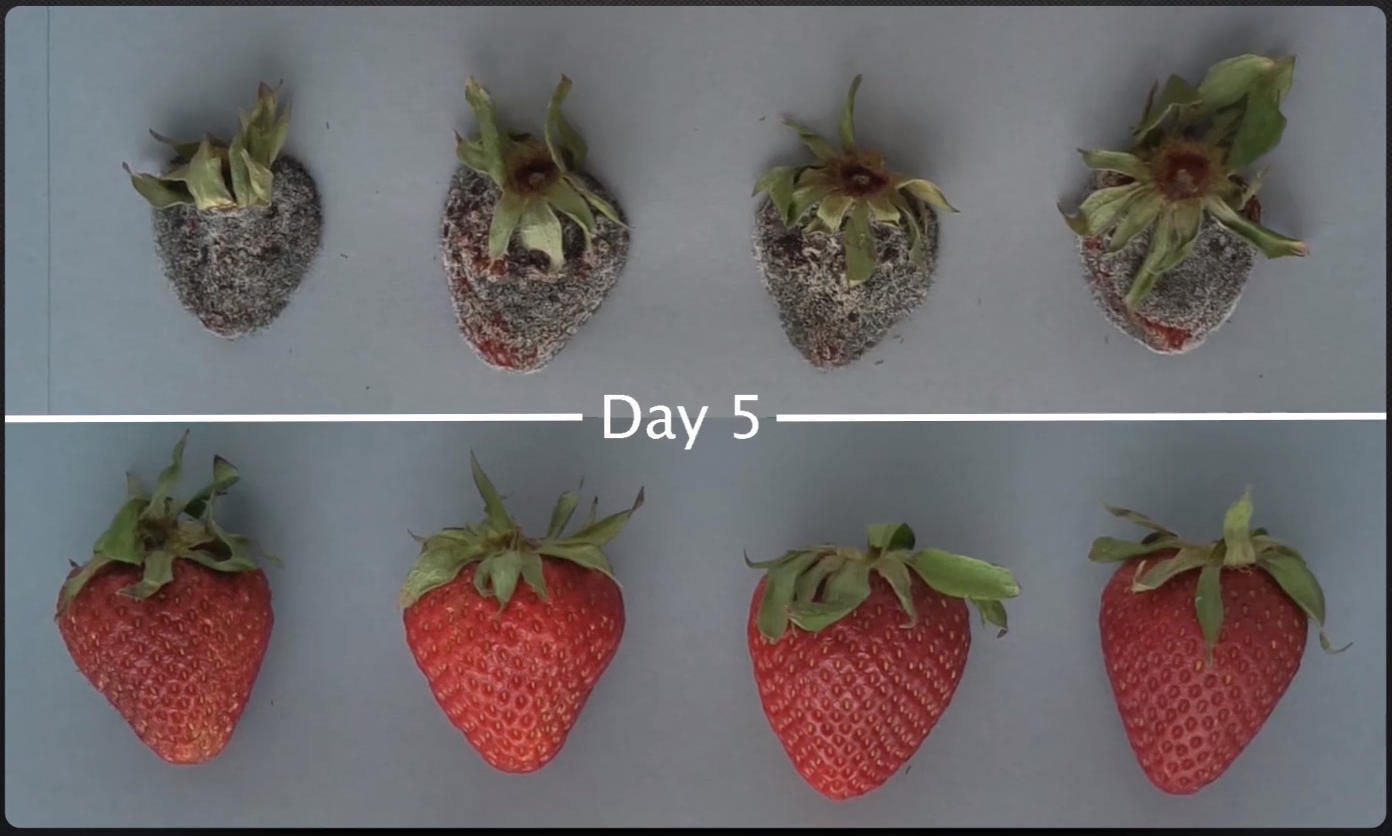

![]() Fig. 2: Strawberries

treated (bottom) versus

untreated (top)

Fig. 2: Strawberries

treated (bottom) versus

untreated (top)

Thermal Time-Saving Techniques

Certainly the most ubiquitous form of managing the fresh produce life cycle is through thermal means, especially the calculated control of temperature (favoring the cold) to intervene and slow the ripening process, while also quelling the growth of unwanted microbes. Cold storage as a technique, like the coating techniques mentioned previously, has been used to prolong the life and preserve the freshness of foods for centuries: before the mechanical refrigerator was commercialized in the late 19th century, the ice trade dominated efforts to prolong the lives of foods in the era of nascent industrialization.[17] Refrigeration today is still one of the most prominent, prevalent, and prolific means used to preserve the life of our produce from initial pick to final plating. The technology eventually extended even into our own domestic realms, with the household refrigerator occupying the last link in the sequence of climate-controlled spaces constituting the gap between producer and eventual consumer.

Today, “more than three-quarters of the food consumed in the United States today is processed, packaged, shipped, stored, and sold under artificial refrigeration,” explains writer Nicola Twilley, writer and researcher who has written extensively on what she dubs “the coldscape,” the constellation of chilled spaces our fresh foods routinely travel through to reach their destinations in an optimum state, ready for purchase and immediate consumption.[18] Fresh produce travels through a sequence of cold spaces that lengthen the lifespan of the food, and enable it to be transported vast distances, breaking down limitations of the past. This network of both mobile and fixed spaces constitutes what is colloquially termed the “Cold Chain” among industry workers, and has built precipitates across the country, with notable concentrations around large ports and major cities.[19] The term “Cold Chain” is similar to Twilley’s “coldscape,” but puts an emphasis on the linkages between the spaces in the system, and the movement between these individual parts, whereas the coldscape promotes a pseudo-geographic, almost anthropologic understanding of the cold spaces as constituting a hermetic world within themselves with norms and mores.

![]()

![]() Fig. 3,4: Photograph series by

artist Mark Manjivar,

documenting the

interiors of household

refrigerators across

the American South.

Fig. 3,4: Photograph series by

artist Mark Manjivar,

documenting the

interiors of household

refrigerators across

the American South.

At the commercial scale, the most prevalent built typology to emerge out of this avenue of operation is the cold storage warehouse.[20] These are almost always long-span, windowless, industrial box structures, designed to optimize airflow and climate-control capabilities. The warehouses are places where produce rests in periods of stasis along the way from pick to plate, often just prior to its release to retail outfitters like supermarkets and bodegas. These warehouses are kept at temperatures hovering just above freezing (because fresh food, after all, cannot be frozen at any point in its lifespan), although thermal specifics vary depending on the type of fruit or vegetable being housed in the space.

The warehouses are supplemented and supported, but also increasingly challenged, by the climate-controlled shipping container, known as the “reefer” (a derivative of the longer “refrigerated” container). This is the mobile equivalent of the cold warehouse, and can be credited with the truly vast expansion of the fresh produce market reach, as its invention marked the moment that the cold chain could exist virtually unbroken from pick to plate. Today, climate-controlled transit vehicles like the reefer shipping container, together with the more traditional cold warehouses, can keep the cold chain closed from supplier to retailer.

Moreover, moving beyond temperature, cold storage warehouses and reefers are calibrated to create the exact humidity levels necessitated by the hibernating produce. The monitoring of temperature and humidity go hand in hand in the optimization of conditions for the produce’s livelihood, which can vary widely depending on which type of fruit or vegetable is being handled. Each of these climatic variables is typically controlled remotely, sometimes automatically, to the utmost degree of precision. Tremendous advancements in technology and its innovative implementation and application in new spaces like the reefer have bolstered the fresh produce supply and distribution industry and its delicate, complex supply chain. It is now possible to have near constant sensor and satellite communications monitoring and tweaking at every step of the way, even for refrigerated containers at sea, or on the backs of tractor-trailers crossing the nation.

![]() Fig. 5: Cold storage

warehouse space

exterior in New Jersey.

Fig. 5: Cold storage

warehouse space

exterior in New Jersey.

The advent of refrigeration, and its application at the industrial, commercial, and domestic scales have completely changed the relationship between consumer and food. Gone are the days when produce was bought and consumed on a regular, daily basis. Today, fruits and vegetables are frequently purchased well ahead of the time of intended use, and often even out of season. Nicola Twilley adeptly summarizes the impact the proliferation of these cold spaces have had on our modern diets and our contemporary economy, making a case echoed also in Michael Osman’s research on these cold spaces, namely that they have been instrumental in orchestrating the shift from food as quotidian necessity for individual and household sustenance, to food as global commodity to be bought, sold and traded like any other dry commodity, including as a speculative investment tool (and as futures, as Osman highlights):

“Artificial refrigeration has reconfigured the contents of our plates and the shape of our cities… Perhaps most bizarrely, although their variations in form reflect the particular requirements of the perishable product they host, coldspaces have, in turn, redesigned food itself, both in terms of the selective breeding that favors cold-tolerance over taste and the more fundamental transition from food as daily nourishment to food as global commodity.”[21]

These spaces which populate the entirety of the fresh produce supply chain have completely reformulated our markets, but also our eating habits, detaching us from seasonality of availability almost entirely.

![]()

![]() Fig. 6, 7: Cold storage spaces

for produce, built by

American Walk in

Coolers (bottom) and MSA

Systems, Inc. (top).

Fig. 6, 7: Cold storage spaces

for produce, built by

American Walk in

Coolers (bottom) and MSA

Systems, Inc. (top).

Constituting Freshness Chemically

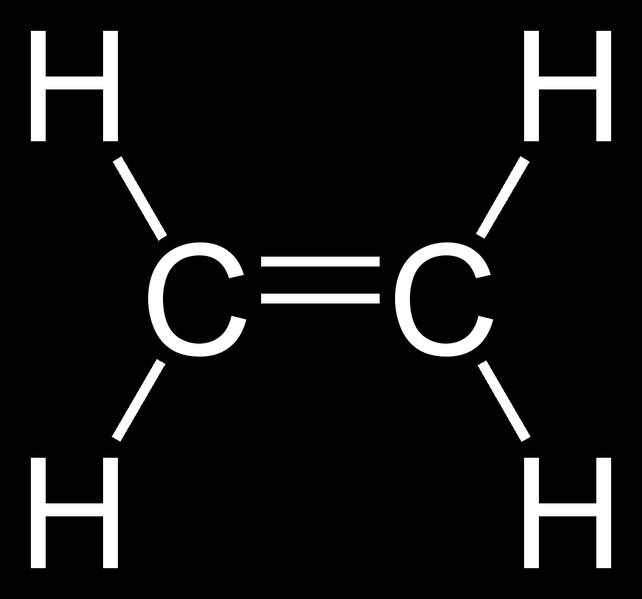

Another means of intervening and manipulating the produce lifespan is through chemicals like ethylene. Ethylene is the naturally-occurring plant hormone mentioned above, which triggers and sustains the ripening process.

![]()

Ethylene is a gas, and is responsible for the changes in texture, color, and flavor associated with ripening. As discussed above, ethylene production is the reason certain fruits and vegetables need to be kept apart in transit, so that a ripening fruit releasing ethylene does not prematurely cause other fruits to ripen. Very much conversely, at the end the cold chain, ethylene is used to speed up the ripening of climeratic fruits—especially tomatoes, bananas, pears, and a handful of other fruits—before they are released to points of retail for sale in just the right condition.

The artificial ripening process came into commercial use in the second quarter of the 20th century.[22] Produce caught the eye of governmental authorities aiming to put some controls into a sector of the market which was routinely abused, and welcomed the promise ethylene gave of controlling ripening times, making it possible for demand and supply to fall into better sync with one another at the hands of the commercial distributors and ripeners. Some criticized the use of the gas, saying it gave suppliers the power to create artificial scarcity, and thus command higher prices for their goods. The following quote taken from a 1927 journal article gives a glimpse into the types of abuses and exploits those in the industry would enact in order to feign freshness in their crop prior to the advent of more surefire ways to control ripening and curate freshness:

“One needs only to consult the Notices of Judgment of the Food and Drugs Act to be reminded how often the offense has been committed of artificially dyeing oranges in order to mislead the buying public. Now, it seems, this method of deception is to go into the discard. Ethylene, with its unusual history, is the reason.”[23]

At the time this article was published “the reaction [ethylene triggered][did] not seem to be well worked out,” but today it’s a highly regulated and understood process.[24]

Ethylene gas is very sensitive and combustible, and can be extremely dangerous when used in large quantities, like in these ripening facilities where fruits are fumigated before being sent to retailers. Correspondingly, there is a significant history of ethylene room explosions, particularly tied to banana facilities. As recently as 1999, there have been fatalities, as resulted from an explosion in the Los Angeles-based Pan-American Banana Co. warehouse.[25]

Commercial ripening rooms share many similarities with cold storage warehouses—extreme atmospheric, temperature, and humidity controls—and can be understood as a continuation of the chain, since ripening rooms are commonly kept cool. Like the cold storage warehouses discussed above, however, nowadays ripening rooms are being absorbed by reefers and containers that promise to be able to control the ripening within themselves, eliminating the need for large static warehouses like those operated by Banana Distributors of New York, one of the four main banana-ripening outfitters supplying New York City. Also like the cold chain, ripening rooms and chambers adjust atmospheric settings to reflect the different needs of different produce types.

As was also the case discussed with the cold storage warehouse, the landscape of artificial, chemical-induced ripening rooms distributed around major ports and cities (paralleling the placement of cold storage buildings) have played a key role in facilitating the year-round availability of many climeratic fruits and vegetables. The US’s major “banana ports” offer a good example of this playing out with produce which is largely imported: governmental monitoring spaces inspect imported crop and release it to its ripening chambers before the yellow fruits find their way into bins and onto shelves at our local bodegas, supermarkets, convenience stores, and coffee shops.

In all cases, the mission with these chemical means of curating freshness is about arriving at just the right condition for the fruit or vegetable before delivering it to the end consumer. Before that point, the ripening rooms chock full or ethylene accelerate the ripening process, essentially hacking produce biology in order to meet the demand of the market.

![]() Fig. 8: NYC banana ripeners

and distributors in the

Bronx

Fig. 8: NYC banana ripeners

and distributors in the

Bronx

Conclusion

Physical, thermal and chemical means of preserving freshness operate together and in tandem across the fresh produce supply chain. By no means comprehensive, this examination aimed at taking a cross section through the varied spaces of the global fresh produce supply chain, and all of the unique and complex precipitate spaces along the way dedicated to the task of keeping these commodities fresh.

This complex fresh produce system has revolutionized how we consume food, and the modern diet, yet also creates limitations with regards to produce which is included versus excluded from the commoditized system, as well. Fruits and vegetables that have been bred explicitly to survive the journey through complex networks of food infrastructures are those we most commonly eat today, while more delicate food items like the mangosteen, for example—which is extremely difficult and uneconomical to transport large distances— remain relatively obscure to us precisely because they can not survive lengthy trips once picked.[26]

These systems and correspondent revolutions in shipping and transit technology have made us almost completely aseasonal eaters. This societal shift has not been met with universal acclaim. Speaking in the early 1900s, Ohio Senator Frederic C. Howe spoke out that “the cold storage evil” was not “an agency of universal service and a means of cheapening the price of food, [but] one of the principal agencies of the speculator,” a clear denouncement of the commoditization of the nation’s food supply.[27] Michael Osman also cites the perspective of butcher Herman Hirschauer, who disdained the fact that “cases of poultry yet in stock” had been “killed and packed more than two years ago.”[28] This view is still very applicable today: apples may stay in stock for up to twelve months, lettuce up to four weeks, and carrots up to nine months, for example.[29]

The counter argument to the senator’s and butcher’s arguments frames cold storage as a public utility for the common good, emphasizing its ability to bring prices down and stabilize what was a volatile and unpredictable cycle of availability.[30] Writes Nicola Twilley:

“Gradually, at first, but now completely, in the United States--the first refrigerated nation--and then beyond, a network of artificially chilled warehouses, cabinets, and reefer fleets have elided place and time, reshaping both markets and cities with a promise of a more rational food supply and an end to decay, waste, and disease.”[31]

There is certainly no denying either the benefits nor the losses entailed by fight to conquer the fresh produce supply chain. In either case, questions of logistics interfacing with basic biology in the case of the fresh produce supply chain creates a highly complex network of spaces which are fodder for deeper and more exploratory study. Consumption habits have changed wildly in the past two centuries, and with recent overtake of Whole Foods by Amazon, as well as the advent of the delivery meal kit (of the likes of Blue Apron or Hello Fresh), we are set up to accomodate continued change in our society’s foodways, driven in large part by developments in logistics.

—Run-DMC, Run-DMC, “Rock Box,” 1983

The term “fresh” is laden with positive value assumptions, as evidenced by its slang use to denote high quality, original content in the 1980s hit single “Rock Box” by vanguard hip hop group Run-DMC. The song’s lyrics pit the rappers’ “fresh” rhymes in opposition to the antagonistic quality of staleness. The fresh/stale dialectic the song tees up evokes the use of the term “fresh” in a more quotidian context: as a favorable descriptor applied to the foods we consume. We are taught to value fresh meals (with the kinds of ingredients grown in a kitchen garden, which—as journalist Michael Pollan would formulate it—“your great-great-great-grandmother would recognize as food”) over frozen dishes, and to steer clear of hyper-processed foods (with the kinds of ingredients manufactured in a factory and unceremoniously assigned barely-deciperable, chemical-esque, polysyllabic names).[1]

Freshness invokes quality, and is associated with health, purity, and simplicity. Freshness, especially in reference to produce, engenders certain assumptions, particularly with regards to the sourcing and post-harvest treatment of our food. There is an unspoken, general expectation that “fresh” foods are those which are made available to the consumer in conditions unaltered from their original or natural (another tricky adjective) state—free from chemical adulteration, genetic manipulation, or physical alteration of any sort. Grocers cater to the guise of freshness not only through the use of the term “fresh” in signage and labeling, but through performative acts like misting produce, presenting the shopper with dewy, gleaming fruits and vegetables, seemingly just plucked from the earth.[2]

Moreover, the quality of freshness is often correlated with short geographic distance between source and destination, a topographical reinterpretation of Occam’s razor applied to the modern western diet, equating the shortest distance with simplicity, and simplicity with value.

Contemporary trends in dining and restauration reflect these assumptions: the farm-to-table model, for example, promotes a minimum-distance, minimal-alteration approach to food as it travels from farmer to fork, which is mainly achieved by bypassing commercial vendors and sourcing directly from a select few farms. This model has rapidly become a pinnacle of fine (as in tasty, but also ethical) dining for a well-todo class of conscious consumers.[3] Similarly, “eat local” has become the mantra of a generation of foodies, many of whom recognize and deploy their consumption habits as political choice.

At a time when over half of the world’s population lives in urbanized areas, removed from the sources of the agricultural products that provide its sustenance, the “fresh” label attempts to frame a (admittedly superficial) shared understanding of the sources of our food.[4] Despite most peoples’ distance or removal from the practice of agriculture, the designation “fresh” provides a semblance of comfort through the assumed control members of society can exercise over their diets through choices made regularly at the grocery store.

Defining Freshness: Labeling, Legalities, and Loopholes

Fittingly, “fresh” has become a widespread label used in the branding, marketing, and advertising of food products as varied as milk, poultry, meat, juice, and of course produce. Though all have all laid claim to the adjective, the precise meaning “fresh” carries in these diverse circumstances varies significantly depending on the item in question: fresh milk implies something different than fresh rutabaga, or freshsqueezed orange juice, for example. Prior to 1993, the use of the term was unregulated, but the repeated “misuse” of the descriptor (and its cousin “freshly”) prompted the Food and Drug Administration (FDA) to propose a legalized definition of the modifier and establish federal regulations to govern its use on labels and packaging.[5] These were enacted into law in 1994, following an open discussion in which industry experts, government officials, and the general public were invited to participate.[6]

In 2000, the FDA held yet another open hearing to determine whether to amend the definition of “fresh” in light of several novel technologies available to extend the shelf life of produce, like the use of pulsed electric fields and of high pressure processing.[7] The questions posed at both the 1993 and 2000 meetings reveal the fraught nature of these discussions involving many players—lobbyists, activists, consumers, producers, retailers, shippers, distributors, lawmakers—with often-competing motivations, and the challenges of setting standards to universalize a largely subjective quality like freshness:

Do consumers associate the term “fresh” with organoleptic [sensory], nutritional, or some other characteristics? What does industry think “fresh” means? Are there quantifiable parameters, e.g., level of nutrients or vitamins, that could be measured to determine if a food is “fresh?” Do consumers want a way to identify foods that taste and look fresh but have been processed to control pathogens?[8]

The more general questions latent in these pointed inquiries include: Is it possible to measure freshness?[9], When is it okay to distinguish something as fresh? Does freshness exist on a spectrum? Or is it a switch, something either present or not? As of 2017, the regulations remain the same as when they were originally instituted in 1993. The code reads as follows:

“The term fresh, when used on the label or in labeling of a food in a manner that suggests or implies that the food is unprocessed, means that the food is in its raw state and has not been frozen or subjected to any form of thermal processing or any other form of preservation.”[10]

The following exceptions are then called out, which do not preclude food from being deemed “fresh”:

1. the addition of approved waxes or coatings;

2. the post-harvest use of approved pesticides;

3. the application of a mild chlorine wash or mild acid wash on produce; or

4. the treatment of raw foods with ionizing radiation. [11]

This list of exemptions begins to hint at the immense logistical apparatus that the fresh produce supply chain participates in, breaking the illusion of the “fresh” as having been subject to minimal intervention and foregrounding instead the sequence of spaces and processes dedicated to preserving freshness along the supply chain, particularly the fresh produce supply chain. This network of spaces and operations devoted to freshness will be dissected in the following pages.

Before tackling the produce supply chain as spatialized network, it is worth noting a few key facts about plant biology which ultimately constitute the raison-d’être of the network’s various precipitate operations. Many of the difficulties surrounding the definition and establishment of precise guidelines concerning “freshness” have to do with the term’s application to produce, which, by definition, is alive: it breathes, respires, transpires, matures, and eventually dies. Freshness, therefore, is always a moving target, uniquely constituted in each of the hundreds of varieties of fruits and vegetables that travel through the logistical systems of produce distribution networks across the country every day. Because it is tasked with the tremendous challenge of keeping produce healthy through journeys often totaling hundreds, if not thousands, of miles between harvest and consumption locations, the fresh produce supply chain is the most complex supply chain in existence. With half of an item’s shelf lift typically spent in transit, the entire constellation of actors, vehicles, spaces, and contexts comprising the fresh produce supply chain is part of a grand-scale fight against the lifecycle of particular fruits and vegetables.[12]

The supply chain is smattered with peculiar spaces whose mission is essentially to hack the process of maturation of the produce it oversees, geared towards the mission of delivering the freshest possible produce to the hands of the consumer at the ultimate point-of-sale, be that a restaurant, bodega, supermarket, or café. The many equipment- and technology-intensive specially-designated spaces involved attempt to rein in the ripening process in order to control and predict the optimal freshness of the crop in their purview.

These are the spaces explored within the remainder of the pages herein, organized into three distinct categories based on the means they employ to manipulate (either through suppression or acceleration) the plant ripening cycle: physical, thermal, and chemical. Rather than provide a comprehensive taxonomy, this examination takes a cross section through the varied spaces constituting the fresh produce supply chain dedicated to the task of keeping these important commodities fresh.

Physical Means of Protecting Perishables

Produce is perishable; it would rot if not consumed within a certain amount of time. As soon as it is harvested, the various processes leading to breakdown begin. These processes can’t be stopped, but can be manipulated—slowed or hastened—and the fresh produce supply chain utilizes various physical means to control this natural cycle, so that the crop ultimately arrives to the consumer in optimum (read fresh) condition. This section addresses both the physical properties of fruits and vegetables, and the physical interventions routinely employed to maintain their attractive characteristics—including flavor, texture, and color—from initial pick to final destination.

All fruits, and many nuts and vegetables, can be classified into one of two categories: climeratic and nonclimeratic. Climeratic fruits continue to ripen after being picked, while non-climeratic fruits do not. For example, apples, bananas, mangoes, peaches, and avocados are climeratic fruits; berries, citrus fruits, and melons are nonclimeratic. Because climeratic fruits release plant hormones which trigger ripening, most notably ethylene, they must be kept away from other plants that are sensitive to these substances, lest the crop ripen and rot prior to reaching its destination.[13] Moreover, certain fruits and vegetables are sensitive to one another’s odors, and will absorb certain scents and flavors, often making for unsavory and unappetizing surprise taste combinations upon consumption. Leeks, for example, are known to pass their pungent, onionlike flavor on to figs and grapes, when stored in close proximity to each other. Green onions are especially licentious vegetables, spreading their flavor and odor to neighboring sweet corn, figs, grapes, mushrooms, and rhubarb, potentially destroying the viability of these latter more delicate-tasting varieties.

Growers, packers, shippers, and distributors therefore organize complex choreographies, in which certain items must be kept apart. In a process akin to crafting elaborate wedding seating charts, industry experts circulate (sometimes colorful) charts and graphics in an attempt to organize the unwieldy biology of these plants into clean, neat visuals summarizing compatibilities between crop types.[14] Though analog and seemingly simplistic, one of the most important means of preserving freshness in crops is to adhere to the appropriate physical separation guidelines removing antagonistic crops from each others’ vicinity. Not doing so could quickly and needlessly compromise a batch of otherwise viable (valuable) crop.

Prescribed positioning aside, another form of physical intervention associated with the fresh produce supply chain is the addition of (FDA-approved) wax coatings on produce. The wax treatment adds an virtually imperceptible, protective, tasteless, odorless layer to certain fruits and vegetables, including apples and peppers, which shield them from microbes while also extending their shelf lives by preventing dehydration. The Edipeel is one such waxing technology being developed; it is among the newest to hit the market, with a planned release this year.[15] These coatings—which are typically either natural-lipid- or petroleum-based—have the secondary effect of making items look more aesthetically pleasing through the added shine and glisten they often provide. Though the Edipeel certainly represents the newest of the type, protective produce coatings have been around for centuries: in the 12th and 13th centuries, Chinese citrusgrowers would pack their crop into wooden boxes, for example, before filling the boxes with wax.[16]

Fig. 1: lemon treated with Edipeel (right) versus without treatment (left)

Fig. 2: Strawberries

treated (bottom) versus

untreated (top)

Fig. 2: Strawberries

treated (bottom) versus

untreated (top)Thermal Time-Saving Techniques

Certainly the most ubiquitous form of managing the fresh produce life cycle is through thermal means, especially the calculated control of temperature (favoring the cold) to intervene and slow the ripening process, while also quelling the growth of unwanted microbes. Cold storage as a technique, like the coating techniques mentioned previously, has been used to prolong the life and preserve the freshness of foods for centuries: before the mechanical refrigerator was commercialized in the late 19th century, the ice trade dominated efforts to prolong the lives of foods in the era of nascent industrialization.[17] Refrigeration today is still one of the most prominent, prevalent, and prolific means used to preserve the life of our produce from initial pick to final plating. The technology eventually extended even into our own domestic realms, with the household refrigerator occupying the last link in the sequence of climate-controlled spaces constituting the gap between producer and eventual consumer.

Today, “more than three-quarters of the food consumed in the United States today is processed, packaged, shipped, stored, and sold under artificial refrigeration,” explains writer Nicola Twilley, writer and researcher who has written extensively on what she dubs “the coldscape,” the constellation of chilled spaces our fresh foods routinely travel through to reach their destinations in an optimum state, ready for purchase and immediate consumption.[18] Fresh produce travels through a sequence of cold spaces that lengthen the lifespan of the food, and enable it to be transported vast distances, breaking down limitations of the past. This network of both mobile and fixed spaces constitutes what is colloquially termed the “Cold Chain” among industry workers, and has built precipitates across the country, with notable concentrations around large ports and major cities.[19] The term “Cold Chain” is similar to Twilley’s “coldscape,” but puts an emphasis on the linkages between the spaces in the system, and the movement between these individual parts, whereas the coldscape promotes a pseudo-geographic, almost anthropologic understanding of the cold spaces as constituting a hermetic world within themselves with norms and mores.

Fig. 3,4: Photograph series by

artist Mark Manjivar,

documenting the

interiors of household

refrigerators across

the American South.

Fig. 3,4: Photograph series by

artist Mark Manjivar,

documenting the

interiors of household

refrigerators across

the American South.At the commercial scale, the most prevalent built typology to emerge out of this avenue of operation is the cold storage warehouse.[20] These are almost always long-span, windowless, industrial box structures, designed to optimize airflow and climate-control capabilities. The warehouses are places where produce rests in periods of stasis along the way from pick to plate, often just prior to its release to retail outfitters like supermarkets and bodegas. These warehouses are kept at temperatures hovering just above freezing (because fresh food, after all, cannot be frozen at any point in its lifespan), although thermal specifics vary depending on the type of fruit or vegetable being housed in the space.

The warehouses are supplemented and supported, but also increasingly challenged, by the climate-controlled shipping container, known as the “reefer” (a derivative of the longer “refrigerated” container). This is the mobile equivalent of the cold warehouse, and can be credited with the truly vast expansion of the fresh produce market reach, as its invention marked the moment that the cold chain could exist virtually unbroken from pick to plate. Today, climate-controlled transit vehicles like the reefer shipping container, together with the more traditional cold warehouses, can keep the cold chain closed from supplier to retailer.

Moreover, moving beyond temperature, cold storage warehouses and reefers are calibrated to create the exact humidity levels necessitated by the hibernating produce. The monitoring of temperature and humidity go hand in hand in the optimization of conditions for the produce’s livelihood, which can vary widely depending on which type of fruit or vegetable is being handled. Each of these climatic variables is typically controlled remotely, sometimes automatically, to the utmost degree of precision. Tremendous advancements in technology and its innovative implementation and application in new spaces like the reefer have bolstered the fresh produce supply and distribution industry and its delicate, complex supply chain. It is now possible to have near constant sensor and satellite communications monitoring and tweaking at every step of the way, even for refrigerated containers at sea, or on the backs of tractor-trailers crossing the nation.

Fig. 5: Cold storage

warehouse space

exterior in New Jersey.

Fig. 5: Cold storage

warehouse space

exterior in New Jersey.The advent of refrigeration, and its application at the industrial, commercial, and domestic scales have completely changed the relationship between consumer and food. Gone are the days when produce was bought and consumed on a regular, daily basis. Today, fruits and vegetables are frequently purchased well ahead of the time of intended use, and often even out of season. Nicola Twilley adeptly summarizes the impact the proliferation of these cold spaces have had on our modern diets and our contemporary economy, making a case echoed also in Michael Osman’s research on these cold spaces, namely that they have been instrumental in orchestrating the shift from food as quotidian necessity for individual and household sustenance, to food as global commodity to be bought, sold and traded like any other dry commodity, including as a speculative investment tool (and as futures, as Osman highlights):

“Artificial refrigeration has reconfigured the contents of our plates and the shape of our cities… Perhaps most bizarrely, although their variations in form reflect the particular requirements of the perishable product they host, coldspaces have, in turn, redesigned food itself, both in terms of the selective breeding that favors cold-tolerance over taste and the more fundamental transition from food as daily nourishment to food as global commodity.”[21]

These spaces which populate the entirety of the fresh produce supply chain have completely reformulated our markets, but also our eating habits, detaching us from seasonality of availability almost entirely.

Fig. 6, 7: Cold storage spaces

for produce, built by

American Walk in

Coolers (bottom) and MSA

Systems, Inc. (top).

Fig. 6, 7: Cold storage spaces

for produce, built by

American Walk in

Coolers (bottom) and MSA

Systems, Inc. (top).Constituting Freshness Chemically

Another means of intervening and manipulating the produce lifespan is through chemicals like ethylene. Ethylene is the naturally-occurring plant hormone mentioned above, which triggers and sustains the ripening process.

Ethylene is a gas, and is responsible for the changes in texture, color, and flavor associated with ripening. As discussed above, ethylene production is the reason certain fruits and vegetables need to be kept apart in transit, so that a ripening fruit releasing ethylene does not prematurely cause other fruits to ripen. Very much conversely, at the end the cold chain, ethylene is used to speed up the ripening of climeratic fruits—especially tomatoes, bananas, pears, and a handful of other fruits—before they are released to points of retail for sale in just the right condition.

The artificial ripening process came into commercial use in the second quarter of the 20th century.[22] Produce caught the eye of governmental authorities aiming to put some controls into a sector of the market which was routinely abused, and welcomed the promise ethylene gave of controlling ripening times, making it possible for demand and supply to fall into better sync with one another at the hands of the commercial distributors and ripeners. Some criticized the use of the gas, saying it gave suppliers the power to create artificial scarcity, and thus command higher prices for their goods. The following quote taken from a 1927 journal article gives a glimpse into the types of abuses and exploits those in the industry would enact in order to feign freshness in their crop prior to the advent of more surefire ways to control ripening and curate freshness:

“One needs only to consult the Notices of Judgment of the Food and Drugs Act to be reminded how often the offense has been committed of artificially dyeing oranges in order to mislead the buying public. Now, it seems, this method of deception is to go into the discard. Ethylene, with its unusual history, is the reason.”[23]

At the time this article was published “the reaction [ethylene triggered][did] not seem to be well worked out,” but today it’s a highly regulated and understood process.[24]

Ethylene gas is very sensitive and combustible, and can be extremely dangerous when used in large quantities, like in these ripening facilities where fruits are fumigated before being sent to retailers. Correspondingly, there is a significant history of ethylene room explosions, particularly tied to banana facilities. As recently as 1999, there have been fatalities, as resulted from an explosion in the Los Angeles-based Pan-American Banana Co. warehouse.[25]

Commercial ripening rooms share many similarities with cold storage warehouses—extreme atmospheric, temperature, and humidity controls—and can be understood as a continuation of the chain, since ripening rooms are commonly kept cool. Like the cold storage warehouses discussed above, however, nowadays ripening rooms are being absorbed by reefers and containers that promise to be able to control the ripening within themselves, eliminating the need for large static warehouses like those operated by Banana Distributors of New York, one of the four main banana-ripening outfitters supplying New York City. Also like the cold chain, ripening rooms and chambers adjust atmospheric settings to reflect the different needs of different produce types.

As was also the case discussed with the cold storage warehouse, the landscape of artificial, chemical-induced ripening rooms distributed around major ports and cities (paralleling the placement of cold storage buildings) have played a key role in facilitating the year-round availability of many climeratic fruits and vegetables. The US’s major “banana ports” offer a good example of this playing out with produce which is largely imported: governmental monitoring spaces inspect imported crop and release it to its ripening chambers before the yellow fruits find their way into bins and onto shelves at our local bodegas, supermarkets, convenience stores, and coffee shops.

In all cases, the mission with these chemical means of curating freshness is about arriving at just the right condition for the fruit or vegetable before delivering it to the end consumer. Before that point, the ripening rooms chock full or ethylene accelerate the ripening process, essentially hacking produce biology in order to meet the demand of the market.

Fig. 8: NYC banana ripeners

and distributors in the

Bronx

Fig. 8: NYC banana ripeners

and distributors in the

BronxConclusion

Physical, thermal and chemical means of preserving freshness operate together and in tandem across the fresh produce supply chain. By no means comprehensive, this examination aimed at taking a cross section through the varied spaces of the global fresh produce supply chain, and all of the unique and complex precipitate spaces along the way dedicated to the task of keeping these commodities fresh.

This complex fresh produce system has revolutionized how we consume food, and the modern diet, yet also creates limitations with regards to produce which is included versus excluded from the commoditized system, as well. Fruits and vegetables that have been bred explicitly to survive the journey through complex networks of food infrastructures are those we most commonly eat today, while more delicate food items like the mangosteen, for example—which is extremely difficult and uneconomical to transport large distances— remain relatively obscure to us precisely because they can not survive lengthy trips once picked.[26]

These systems and correspondent revolutions in shipping and transit technology have made us almost completely aseasonal eaters. This societal shift has not been met with universal acclaim. Speaking in the early 1900s, Ohio Senator Frederic C. Howe spoke out that “the cold storage evil” was not “an agency of universal service and a means of cheapening the price of food, [but] one of the principal agencies of the speculator,” a clear denouncement of the commoditization of the nation’s food supply.[27] Michael Osman also cites the perspective of butcher Herman Hirschauer, who disdained the fact that “cases of poultry yet in stock” had been “killed and packed more than two years ago.”[28] This view is still very applicable today: apples may stay in stock for up to twelve months, lettuce up to four weeks, and carrots up to nine months, for example.[29]

The counter argument to the senator’s and butcher’s arguments frames cold storage as a public utility for the common good, emphasizing its ability to bring prices down and stabilize what was a volatile and unpredictable cycle of availability.[30] Writes Nicola Twilley:

“Gradually, at first, but now completely, in the United States--the first refrigerated nation--and then beyond, a network of artificially chilled warehouses, cabinets, and reefer fleets have elided place and time, reshaping both markets and cities with a promise of a more rational food supply and an end to decay, waste, and disease.”[31]

There is certainly no denying either the benefits nor the losses entailed by fight to conquer the fresh produce supply chain. In either case, questions of logistics interfacing with basic biology in the case of the fresh produce supply chain creates a highly complex network of spaces which are fodder for deeper and more exploratory study. Consumption habits have changed wildly in the past two centuries, and with recent overtake of Whole Foods by Amazon, as well as the advent of the delivery meal kit (of the likes of Blue Apron or Hello Fresh), we are set up to accomodate continued change in our society’s foodways, driven in large part by developments in logistics.

1. Michael Pollan, Food Rules: An Eater’s Manual (New York: Penguin Books, 2009).

2. “To get the ‘fresh’ image misting allows,” as written on the industry website Produce Business, “it’s important to remove broken leaves from the display, cut butt ends of leafy vegetables and clean any dirt from the display area... It is also important to discard dead or old produce and restock with produce that has been properly crisped and cleaned. Older produce goes on top if it is still saleable. Always rotate displays to keep them full and inviting.” This laundry list of tips highlights the time and effort grocers commit to curating their displays to convey freshness, an important characteristic to communicate in enticing customers to purchase their produce. Doug Ohlemeier, “Successfully Merchandising Wet Rack Produce,” Produce Business, March 1 2018, accessed May 8 2018, https://www.producebusiness.com/successfully-merchandising-wet-rack-produce/.

3. Geographer Suzanne Friedberg points out that access to fresh foods has often corresponded to wealth and social class throughout history, highlighting an important aspect to keep in mind regarding such trends as the “locavore” movement. She also notes that eating local has reinvigorated small farmers in some parts of the country (such as outside of New York and San Francisco, where this form of consciousness is in vogue) but it has by no means been universally good for farmers globally. Suzanne Friedberg, Fresh: A Perishable History (Cambridge: Belknap Press, 2010), 7-10.

4. Carolyn Steel, Hungry City: How Food Spaces our Lives (London: Vintage Books, 2009), 8.

5. The FDA manages the labeling guidelines associated with produce, and the USDA oversees the analogous guidelines pertaining to poultry and meat. For the purposes of this paper, which takes the fresh produce supply chain as its main focus, only the FDA definition will be examined.

6. Food and Drug Administration Department of Health and Human Services, “Food Labeling: Nutrient Content Claims, General Principles, Petitions, Definition of Terms; Definitions of Nutrient Content Claims for the Fat, Fatty Acid, and Cholesterol Content of Food” Federal Register. Vol. 58, No. 3, 1993, 2401-24, https://www.fda.gov/ downloads/AdvisoryCommittees/CommitteesMeetingMaterials/FoodAdvisoryCommittee/UCM248504.pdf

7. Pulsed electric field processing is not widely adopted, but uses short, high-voltage electric pulses to kill microbes. High pressure processing also targets microbes, but through the use of hyperbaric chambers. Suzanne Friedberg discusses the meeting in greater detail in her introduction to Fresh. Friedberg, 1-14.

8. Food and Drug Administration Department of Health and Human Services, “Food Labeling; Use of the Term ‘Fresh’ for Foods Processed With Alternative Nonthermal Technologies; Public Meeting,” Federal Register, Vol. 65 No. 128, 2000, https://www. federalregister.gov/documents/2000/07/03/00-16716/food-labeling-use-of-theterm-fresh-for-foods-processed-with-alternative-nonthermal-technologies

9. The closest approximation to a system for quantifying freshness in use is the system of “sell by,” “best if used by,” and “use by” stickers often affixed to food items. These have their own interesting history of use, regulation, and naming shifts. Interestingly enough, only infant formula is required by federal law to be labeled with such a date. For more on these labels, see “Food Product Dating,” United States Department of Agriculture, December 14 2016, accessed May 10 2018. https://www.fsis. usda.gov/wps/portal/fsis/topics/food-safety-education/get-answers/food-safetyfact-sheets/food-labeling/food-product-dating/food-product-dating.

10. Certain commonly-processed foods are exempt from these rules, like milk, which consumers expect to be processed (pasteurized). FDA HHS, “Use of the Term ‘Fresh,’” 2000.

11. Ibid.

12. Rob O’Byrne, “Seven Things That Matter Most to Fresh Supply Chain Leaders,” Logistics Bureau, October 24 2016, access May 8 2018, https://www.logisticsbureau.com/7-things-that-matter-most-to-fresh-supply-chain-leaders.

13. This chain-reaction-like sequence of events can be witnessed on a much smaller scale within the household refrigerator or countertop. A ripening banana placed next to an unripe apple will cause the apple to ripen more quickly than it would have if isolated.

14. For an example, see “Capital Produce Distributors, Inc. Fresh Produce and Handling Guide,” Capital Produce Distributors, Imro, SC, http://capitalproduce.com/ wp-content/uploads/2016/12/PRODUCE-STORAGE-AND-HANDLING-GUIDE.pdf.

15. “Edipeel” Apeel Sciences, Goleta, CA, accessed May 8 2018, http://apeelsciences. com/index.html.

16. Julia Phillips, “Why Fruit Has a Fake Wax Coating,” The Atlantic, April 27 2017, accessed May 8 2018, https://www.theatlantic.com/technology/archive/2017/04/ why-fruit-has-a-fake-wax-coating/524619/.

17. Jonathan Rees, Refrigeration Nation: A History of Ice, Appliances, and Enterprise in America, (Baltimore: Johns Hopkins University Press, 2013), 1-10.

18. Nicola Twilley, “Coldscape,” Cabinet Magazine, Issue 47, Fall 2012.

19. For a partial map curated by Nicola Twilley, see “Perishable: An Exploration of the Refrigerated Landscape of American,” The Center for Land Use Interpretation, accessed April 8 2018, http://www.clui.org/content/perishable-exploration-refrigerated-landscape-america.

20. Michael Osman discusses the cold storage warehouse extensively in Modernism’s Visible Hand. Osman argues that the cold storage warehouse was pivotal to the establishment of a futures market in produce, a foundational moment building up to the commoditization of the global food supply. Michael Osman, “Cold Storage and the Speculative Market of Preserved Assets,” in Modernism’s Visible Hand: Architecture and Regulation in America, (Minneapolis: University of Minnesota Press, 2018), 45-80.

21. Twilley.

22. Editorial Board, “Artificial Ripening of Fruits by Ethylene,” Journal of the American Medical Association. September 3 1927, accessed April 1 2018, https://jamanetwork.com/journals/jama/fullarticle/249773.

23. Ibid.

24. Ibid.

25. George Ramos, “1 Killed, 5 Hurt in Blast, Fire at Produce Warehouse,” LA Times, July 7 1999, accessed May 8, 2018, http://articles.latimes.com/1999/jul/07/local/ me-53692.

26. In an article written on the mangtosteen, journalist Daniel Stone reported that “The fruit spoiled so fast that someone started the rumor around 1890 that Queen Victoria would grant knighthood to anyone who brought her one. Daniel Stone, “Meet the Mangtosteen,” National Geographic. Online, May 26 2016, accessed May 10 2018, https://www.nationalgeographic.com/people-and-culture/food/the-plate/2016/05/ meet-the-mangosteen/.

27. Osman, 75.

28. Ibid.

29. “Just how old are the 'fresh' fruit & vegetables we eat?” The Guardian, July 13 2003, accessed May 10 2018, https://www.theguardian.com/lifeandstyle/2003/ jul/13/foodanddrink.features18.

30. “By extending the field of speculation to include perishable products… the cold storage system further stabilized the distribution of supply. ‘Fruit, meat, fish, eggs,’ wrote Taussig, ‘no longer come on the market in spasmodic and irregular amounts. Supplies that are heavy at one time are brought by dealers, put in storage, and held for sale at a later period of scantier supply. Prices are more equable, and on the whole the profits of the dealers are probably less. There is less risk to them, and the community gets its supplies at a smaller charge for their services as middlemen.’” Osman, 76.

31. Twilley.

2. “To get the ‘fresh’ image misting allows,” as written on the industry website Produce Business, “it’s important to remove broken leaves from the display, cut butt ends of leafy vegetables and clean any dirt from the display area... It is also important to discard dead or old produce and restock with produce that has been properly crisped and cleaned. Older produce goes on top if it is still saleable. Always rotate displays to keep them full and inviting.” This laundry list of tips highlights the time and effort grocers commit to curating their displays to convey freshness, an important characteristic to communicate in enticing customers to purchase their produce. Doug Ohlemeier, “Successfully Merchandising Wet Rack Produce,” Produce Business, March 1 2018, accessed May 8 2018, https://www.producebusiness.com/successfully-merchandising-wet-rack-produce/.

3. Geographer Suzanne Friedberg points out that access to fresh foods has often corresponded to wealth and social class throughout history, highlighting an important aspect to keep in mind regarding such trends as the “locavore” movement. She also notes that eating local has reinvigorated small farmers in some parts of the country (such as outside of New York and San Francisco, where this form of consciousness is in vogue) but it has by no means been universally good for farmers globally. Suzanne Friedberg, Fresh: A Perishable History (Cambridge: Belknap Press, 2010), 7-10.

4. Carolyn Steel, Hungry City: How Food Spaces our Lives (London: Vintage Books, 2009), 8.

5. The FDA manages the labeling guidelines associated with produce, and the USDA oversees the analogous guidelines pertaining to poultry and meat. For the purposes of this paper, which takes the fresh produce supply chain as its main focus, only the FDA definition will be examined.

6. Food and Drug Administration Department of Health and Human Services, “Food Labeling: Nutrient Content Claims, General Principles, Petitions, Definition of Terms; Definitions of Nutrient Content Claims for the Fat, Fatty Acid, and Cholesterol Content of Food” Federal Register. Vol. 58, No. 3, 1993, 2401-24, https://www.fda.gov/ downloads/AdvisoryCommittees/CommitteesMeetingMaterials/FoodAdvisoryCommittee/UCM248504.pdf

7. Pulsed electric field processing is not widely adopted, but uses short, high-voltage electric pulses to kill microbes. High pressure processing also targets microbes, but through the use of hyperbaric chambers. Suzanne Friedberg discusses the meeting in greater detail in her introduction to Fresh. Friedberg, 1-14.

8. Food and Drug Administration Department of Health and Human Services, “Food Labeling; Use of the Term ‘Fresh’ for Foods Processed With Alternative Nonthermal Technologies; Public Meeting,” Federal Register, Vol. 65 No. 128, 2000, https://www. federalregister.gov/documents/2000/07/03/00-16716/food-labeling-use-of-theterm-fresh-for-foods-processed-with-alternative-nonthermal-technologies

9. The closest approximation to a system for quantifying freshness in use is the system of “sell by,” “best if used by,” and “use by” stickers often affixed to food items. These have their own interesting history of use, regulation, and naming shifts. Interestingly enough, only infant formula is required by federal law to be labeled with such a date. For more on these labels, see “Food Product Dating,” United States Department of Agriculture, December 14 2016, accessed May 10 2018. https://www.fsis. usda.gov/wps/portal/fsis/topics/food-safety-education/get-answers/food-safetyfact-sheets/food-labeling/food-product-dating/food-product-dating.

10. Certain commonly-processed foods are exempt from these rules, like milk, which consumers expect to be processed (pasteurized). FDA HHS, “Use of the Term ‘Fresh,’” 2000.

11. Ibid.

12. Rob O’Byrne, “Seven Things That Matter Most to Fresh Supply Chain Leaders,” Logistics Bureau, October 24 2016, access May 8 2018, https://www.logisticsbureau.com/7-things-that-matter-most-to-fresh-supply-chain-leaders.

13. This chain-reaction-like sequence of events can be witnessed on a much smaller scale within the household refrigerator or countertop. A ripening banana placed next to an unripe apple will cause the apple to ripen more quickly than it would have if isolated.

14. For an example, see “Capital Produce Distributors, Inc. Fresh Produce and Handling Guide,” Capital Produce Distributors, Imro, SC, http://capitalproduce.com/ wp-content/uploads/2016/12/PRODUCE-STORAGE-AND-HANDLING-GUIDE.pdf.

15. “Edipeel” Apeel Sciences, Goleta, CA, accessed May 8 2018, http://apeelsciences. com/index.html.

16. Julia Phillips, “Why Fruit Has a Fake Wax Coating,” The Atlantic, April 27 2017, accessed May 8 2018, https://www.theatlantic.com/technology/archive/2017/04/ why-fruit-has-a-fake-wax-coating/524619/.

17. Jonathan Rees, Refrigeration Nation: A History of Ice, Appliances, and Enterprise in America, (Baltimore: Johns Hopkins University Press, 2013), 1-10.

18. Nicola Twilley, “Coldscape,” Cabinet Magazine, Issue 47, Fall 2012.

19. For a partial map curated by Nicola Twilley, see “Perishable: An Exploration of the Refrigerated Landscape of American,” The Center for Land Use Interpretation, accessed April 8 2018, http://www.clui.org/content/perishable-exploration-refrigerated-landscape-america.

20. Michael Osman discusses the cold storage warehouse extensively in Modernism’s Visible Hand. Osman argues that the cold storage warehouse was pivotal to the establishment of a futures market in produce, a foundational moment building up to the commoditization of the global food supply. Michael Osman, “Cold Storage and the Speculative Market of Preserved Assets,” in Modernism’s Visible Hand: Architecture and Regulation in America, (Minneapolis: University of Minnesota Press, 2018), 45-80.

21. Twilley.

22. Editorial Board, “Artificial Ripening of Fruits by Ethylene,” Journal of the American Medical Association. September 3 1927, accessed April 1 2018, https://jamanetwork.com/journals/jama/fullarticle/249773.

23. Ibid.

24. Ibid.

25. George Ramos, “1 Killed, 5 Hurt in Blast, Fire at Produce Warehouse,” LA Times, July 7 1999, accessed May 8, 2018, http://articles.latimes.com/1999/jul/07/local/ me-53692.

26. In an article written on the mangtosteen, journalist Daniel Stone reported that “The fruit spoiled so fast that someone started the rumor around 1890 that Queen Victoria would grant knighthood to anyone who brought her one. Daniel Stone, “Meet the Mangtosteen,” National Geographic. Online, May 26 2016, accessed May 10 2018, https://www.nationalgeographic.com/people-and-culture/food/the-plate/2016/05/ meet-the-mangosteen/.

27. Osman, 75.

28. Ibid.

29. “Just how old are the 'fresh' fruit & vegetables we eat?” The Guardian, July 13 2003, accessed May 10 2018, https://www.theguardian.com/lifeandstyle/2003/ jul/13/foodanddrink.features18.

30. “By extending the field of speculation to include perishable products… the cold storage system further stabilized the distribution of supply. ‘Fruit, meat, fish, eggs,’ wrote Taussig, ‘no longer come on the market in spasmodic and irregular amounts. Supplies that are heavy at one time are brought by dealers, put in storage, and held for sale at a later period of scantier supply. Prices are more equable, and on the whole the profits of the dealers are probably less. There is less risk to them, and the community gets its supplies at a smaller charge for their services as middlemen.’” Osman, 76.

31. Twilley.