Amazon City

Baolin Shen / 2019

Yale School of Architecture

The influence of Amazon’s online retail platform has reformed the way that retail works. The company has, in the recent years, given significant attention to develop its own logistical systems. In order to improve the efficiency of its product delivery network, Amazon has sought to streamline its logistical process. Apart from building up an extensive network of storage, the company has also invested in technologies to speed up its last-mile deliveries. The promise of a shorter delivery time comes with the incursion of Amazon further into cities, and closer to consumers than ever before.

![]()

Globally, the phenomenal rate at which e-commerce is explanding has radically changed the logistics of retail delivery. Traditionally large shipments of goods have been taken over by millions of deliveries of small personal packages at increased frequencies. Amazon alone accounts for 49.1% of US’s total e-commerce sales which is roughly equivalent to 5% of the country’s total retail sales, and ships more than 1.6 million packages per day. The map above shows the growth of fulfillent centers, sortation centers, grocery facilities and Prime Now hubs in the United States over two decades.

![]()

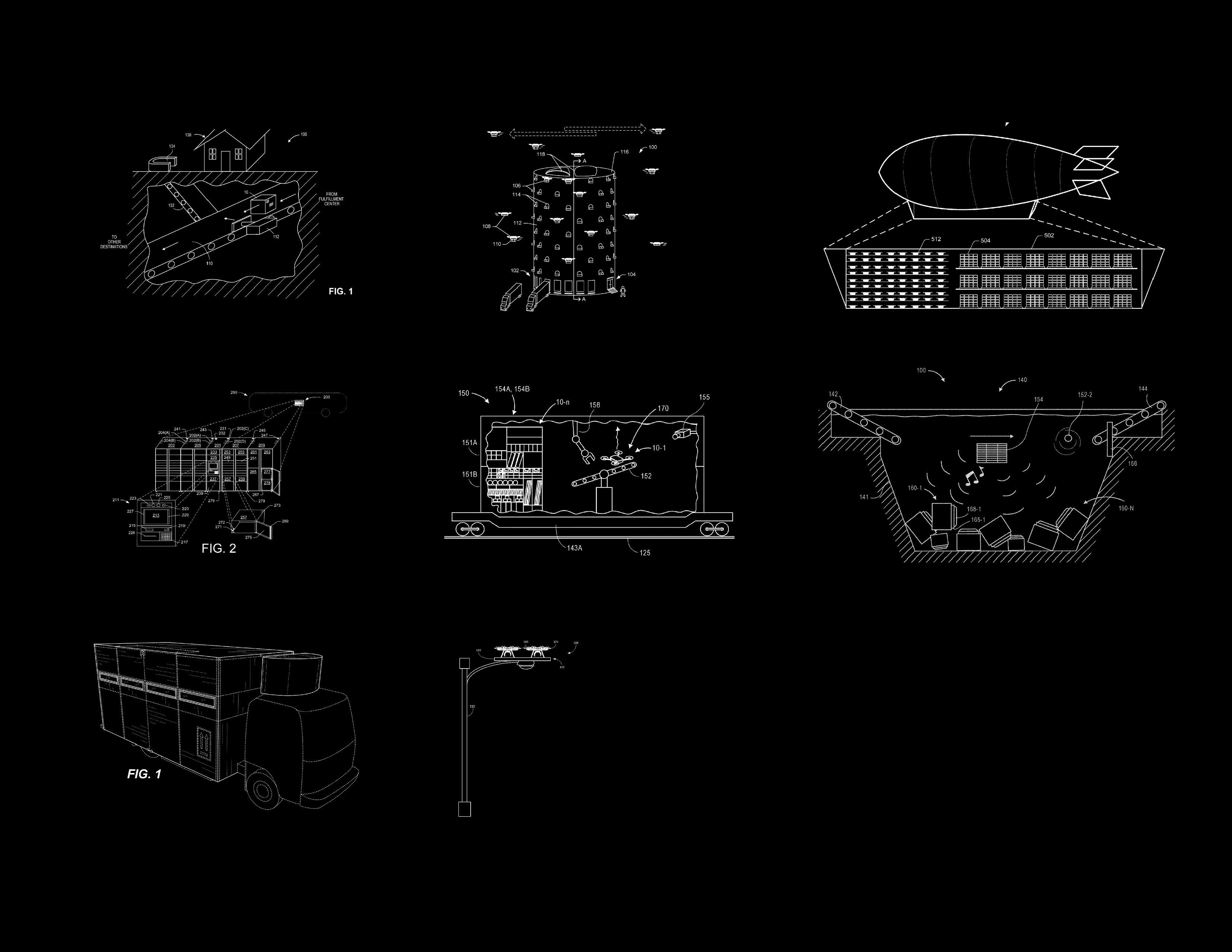

Through the investigation of Amazon patents and delivery strategies, this research examines the methods that the company uses to appropriate urban space for its own logistical space. The project is presented in the format of guidebook that seeks to capture the relationship amongst different logistical components. The guidebook asks: are extant delivery infrastructures, like roads, bike lanes, and public transporation, adapting to keep up with the pace set by Amazon, and if so, how?

![]()

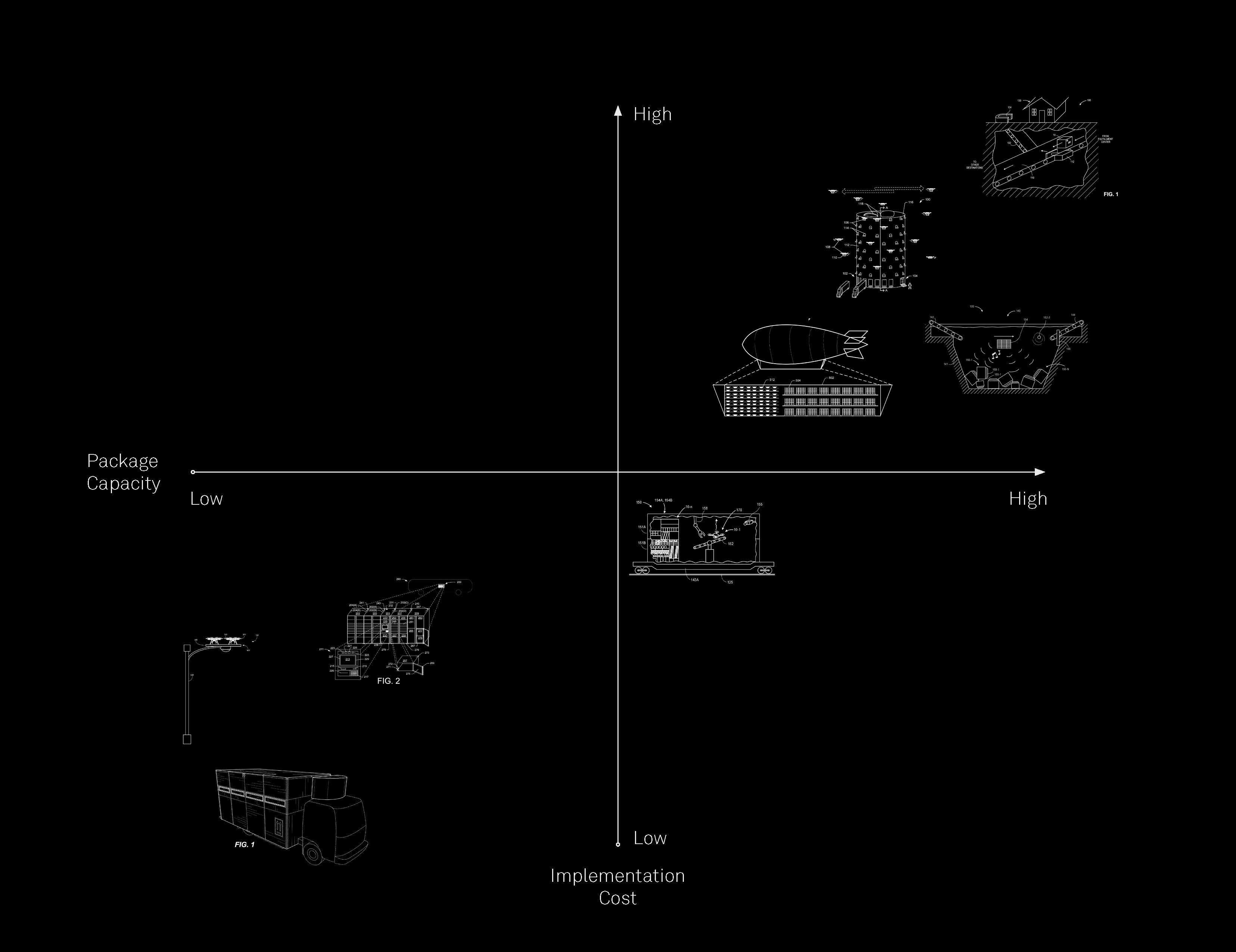

When placed on a graph that pairs package capacity with implimentation cost, it is clear that the traditional method of highway-based delivery services and even cutting-edge technologies, such as drone charging stations, lie at the lower end of the scale, while more fantastical patents and inventions dreamt up by Amazon exist at the upper end of both variables.

![]()

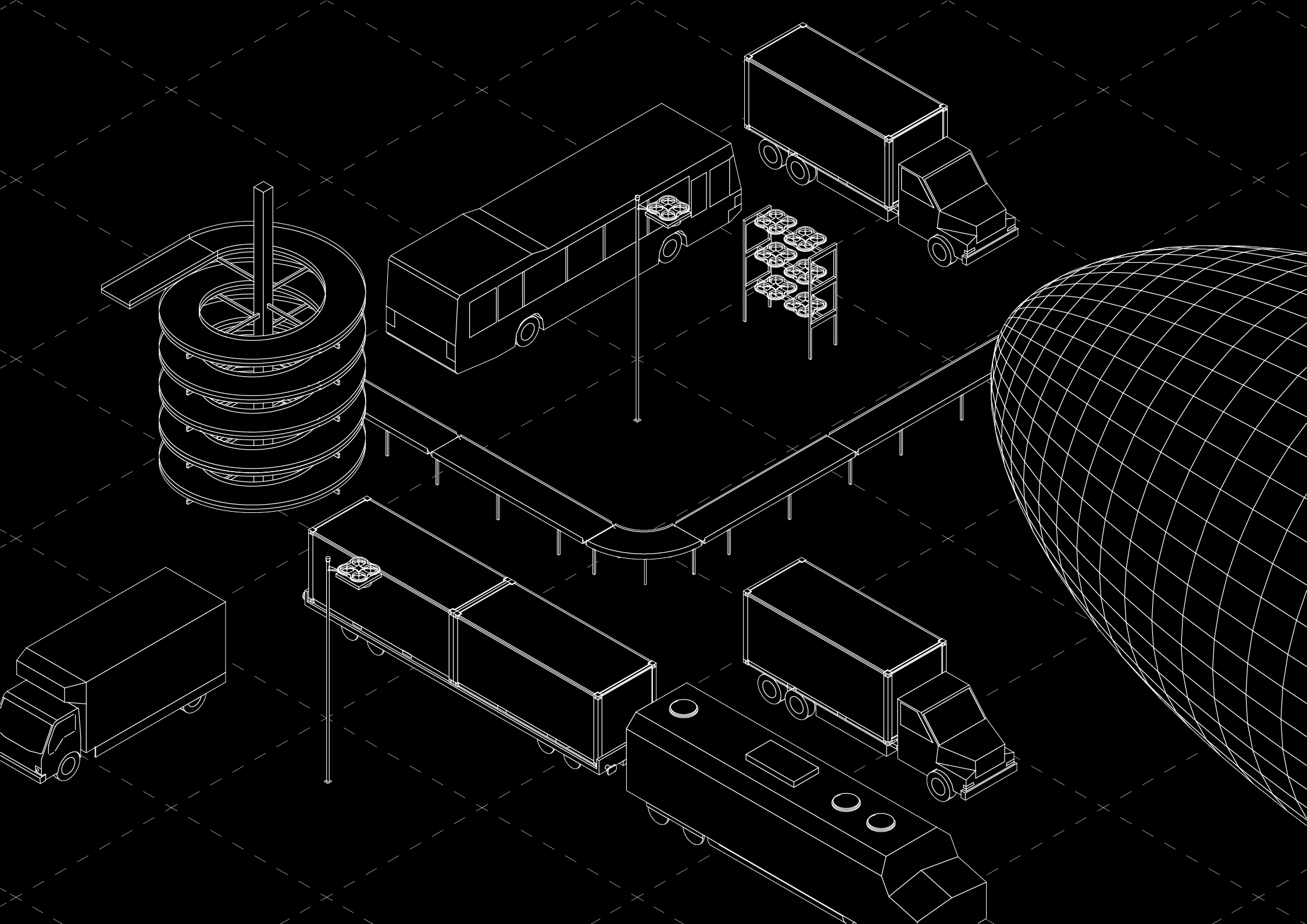

While there are nuances to each delivery system, they each exist as a kit of smaller parts, whether stored on a shelf in Whole Foods, a fulfillment center, or a drone hub.

![]()

Flying Fortress: The aerial fulfillment center that takes advantage of the available airspace above the city to position itself closer to the consumers.

![]()

Moving “Warehouse”: By adapting the functions of a fulfillment center to a modular container, existing networks of transportation, such as trucks and trains, can be utilized for delivery.

![]()

Roadside Charger: Grafted onto existing lamp posts, it charges drones that have finished a delivery, but have insufficient power to return to base.

Tag-along Locker: Smart lockers are installed or attached to public transport, turning them into modes of package delivery.

![]()

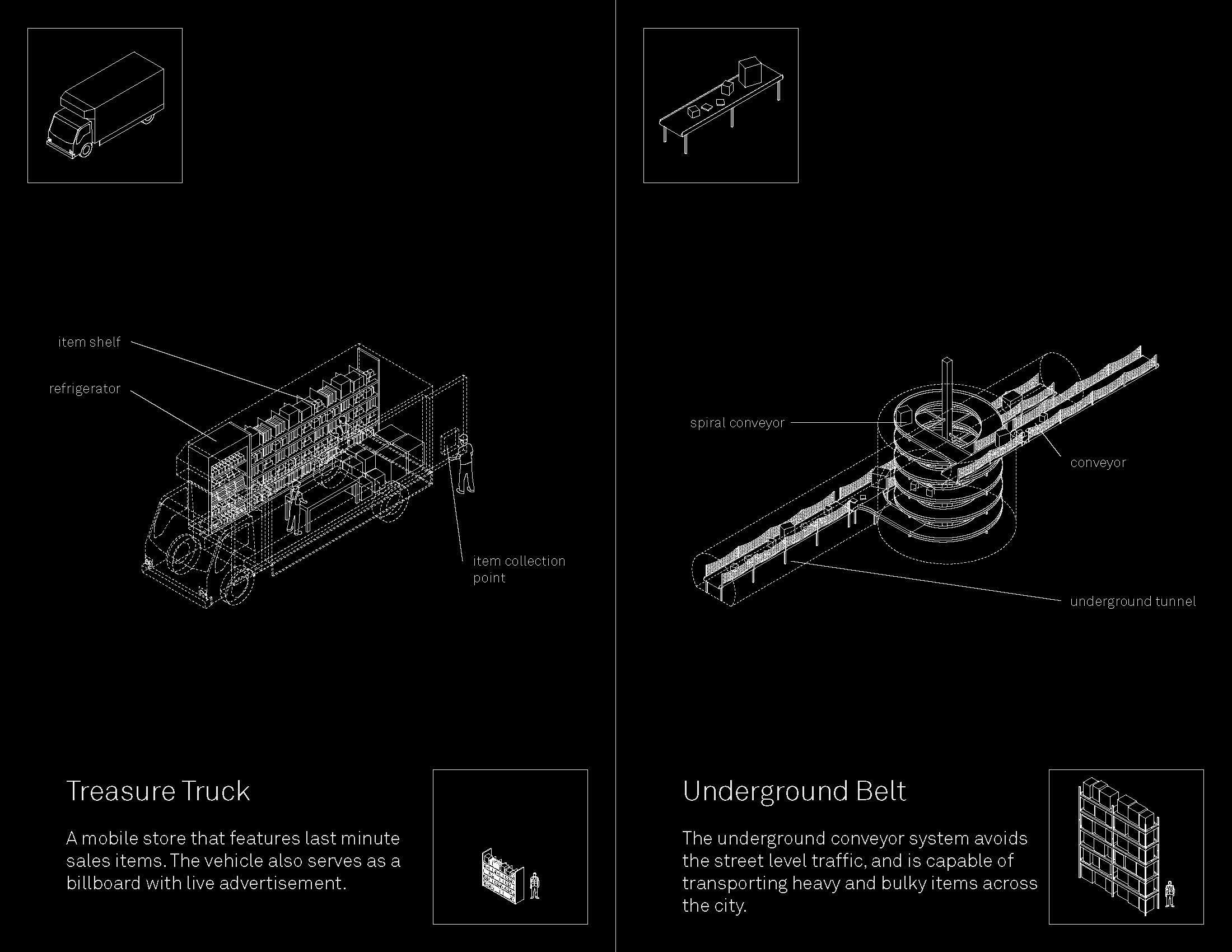

Treasure Truck: A modile store that features last minute sales items. The vehicle also serves as a billboard with live advertisement.

Underground Belt: The under ground conveyor system avoids the street level traffic, and is capable of transporting heavy and bulky items across the city.

Yale School of Architecture

The influence of Amazon’s online retail platform has reformed the way that retail works. The company has, in the recent years, given significant attention to develop its own logistical systems. In order to improve the efficiency of its product delivery network, Amazon has sought to streamline its logistical process. Apart from building up an extensive network of storage, the company has also invested in technologies to speed up its last-mile deliveries. The promise of a shorter delivery time comes with the incursion of Amazon further into cities, and closer to consumers than ever before.

Globally, the phenomenal rate at which e-commerce is explanding has radically changed the logistics of retail delivery. Traditionally large shipments of goods have been taken over by millions of deliveries of small personal packages at increased frequencies. Amazon alone accounts for 49.1% of US’s total e-commerce sales which is roughly equivalent to 5% of the country’s total retail sales, and ships more than 1.6 million packages per day. The map above shows the growth of fulfillent centers, sortation centers, grocery facilities and Prime Now hubs in the United States over two decades.

Through the investigation of Amazon patents and delivery strategies, this research examines the methods that the company uses to appropriate urban space for its own logistical space. The project is presented in the format of guidebook that seeks to capture the relationship amongst different logistical components. The guidebook asks: are extant delivery infrastructures, like roads, bike lanes, and public transporation, adapting to keep up with the pace set by Amazon, and if so, how?

When placed on a graph that pairs package capacity with implimentation cost, it is clear that the traditional method of highway-based delivery services and even cutting-edge technologies, such as drone charging stations, lie at the lower end of the scale, while more fantastical patents and inventions dreamt up by Amazon exist at the upper end of both variables.

While there are nuances to each delivery system, they each exist as a kit of smaller parts, whether stored on a shelf in Whole Foods, a fulfillment center, or a drone hub.

Flying Fortress: The aerial fulfillment center that takes advantage of the available airspace above the city to position itself closer to the consumers.

Moving “Warehouse”: By adapting the functions of a fulfillment center to a modular container, existing networks of transportation, such as trucks and trains, can be utilized for delivery.

Roadside Charger: Grafted onto existing lamp posts, it charges drones that have finished a delivery, but have insufficient power to return to base.

Tag-along Locker: Smart lockers are installed or attached to public transport, turning them into modes of package delivery.

Treasure Truck: A modile store that features last minute sales items. The vehicle also serves as a billboard with live advertisement.

Underground Belt: The under ground conveyor system avoids the street level traffic, and is capable of transporting heavy and bulky items across the city.